Statotherm V Cover seal V901/…

Statotherm V Cover seal V901/…

Statotherm V Cover seal V901/…

Features

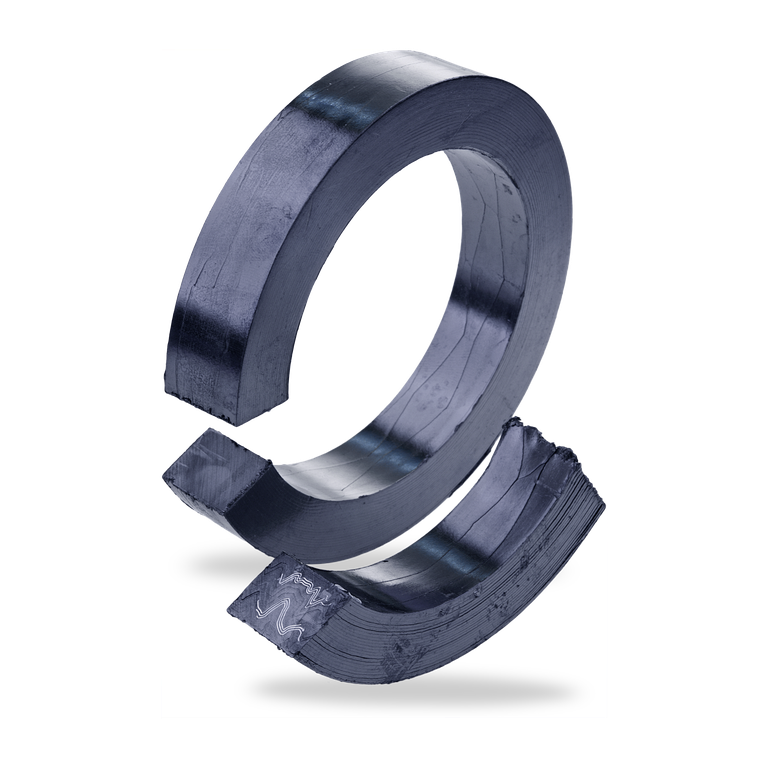

Statotherm V cover seals V901 (self-sealing) are precision-made seals made from permanently elastic, expanded graphite (purity ≥ 99%) without binders or fillers. Cover seals are successfully used as self-sealing closures in high pressure valves, e.g. for power stations at high temperatures and up to 1,000 mm diameter.

Advantages

- Easy to assemble and disassemble

- No damage to the sealing surfaces

- Long service life

- Do not harden

- Optimized sealing result

- Minimum wear of the contact surface

Recommended applications

Industries

- Process industry

- Petrochemical industry

- Chemical industry

- Power plant technology

- Building services industry

- Valves

Variants

Rectangular profile (without, or with one or with two end caps):

V901/R7, V901R7K, V901RKK, V901RWK

V901/R7, V901R7K, V901RKK, V901RWK

Outer chamfer (without, with one or with two caps):

V901/A7, V901A7K, V901AKK

Inner chamfer (without, with one or with two caps):

V901/I7, V901I7K, V901I

For applications in nuclear power plants, with a graphite purity > 99,85%:

V901/7N

Graphite purity > 98%:

V911

Notes

Design and ordering information

The design of the cover seal depends on the pressure and dimensions. Please specify the operating conditions and profile shape with any enquiries or orders (example: pressure in bar, diameter d1 and d2, profile shape I, A or R).

The design of the cover seal depends on the pressure and dimensions. Please specify the operating conditions and profile shape with any enquiries or orders (example: pressure in bar, diameter d1 and d2, profile shape I, A or R).

Forms of supply

- Die-pressed rings, to drawing, measurements or other agreement

Similar products

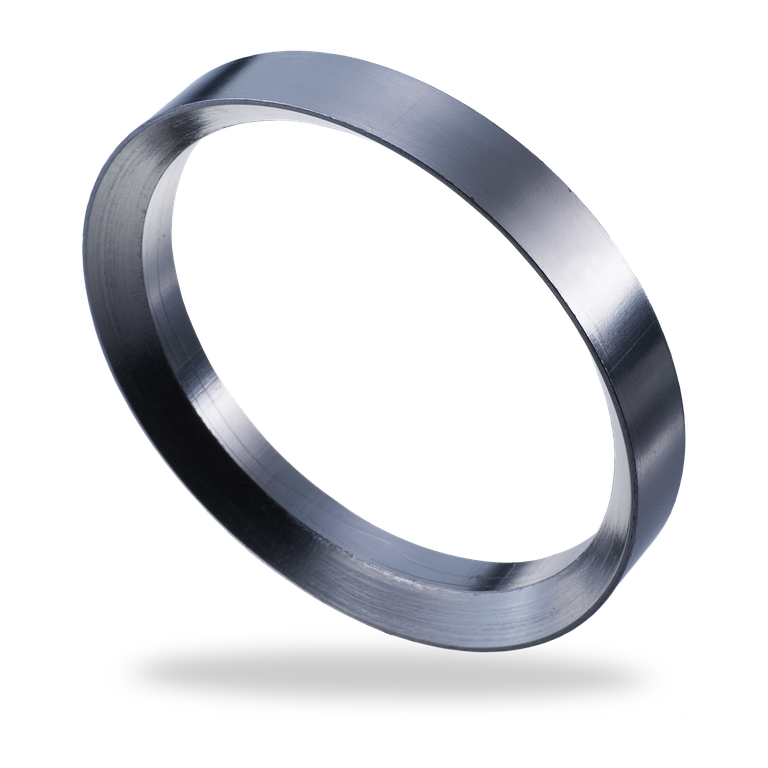

Statotherm R profile rings R901/B..

Statotherm R profile rings R901/B are made from permanently elastic, expanded graphite (purity ≥ 99.85%, ash content ≤0.15 %, chloride content ≤20 ppm) without binders or fillers. Statotherm R profile rings R901/B are almost maintenance-free and are intended for exposure to extreme temperature cycling and/ or high or low temperature ranges which cannot be withstood by elastomeric O-rings.

Statotherm Tape 6750/INC

Statotherm tape 6750/INC is a braided tape made from graphite yarn reinforced with Inconel wires. It also has an adhesive backing.

Statotherm V Cover seal V881-…

Statotherm V cover seals V881 (self-sealing) consist of pure graphite rings (purity > 99%) with an embedded stainless steel reinforcement. They are used in particular in applications with large gaps and high pressures. For example, Statotherm V cover seals V881 are used successfully in power stations at high temperatures and with diameters of up to 1,000 mm.