Mtex Dual seals

Mtex Dual seals

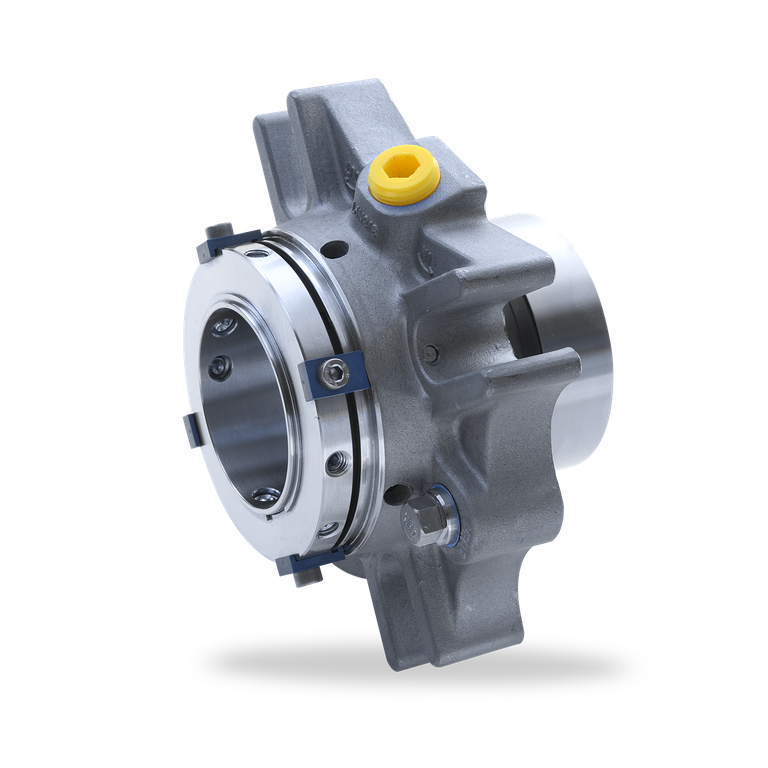

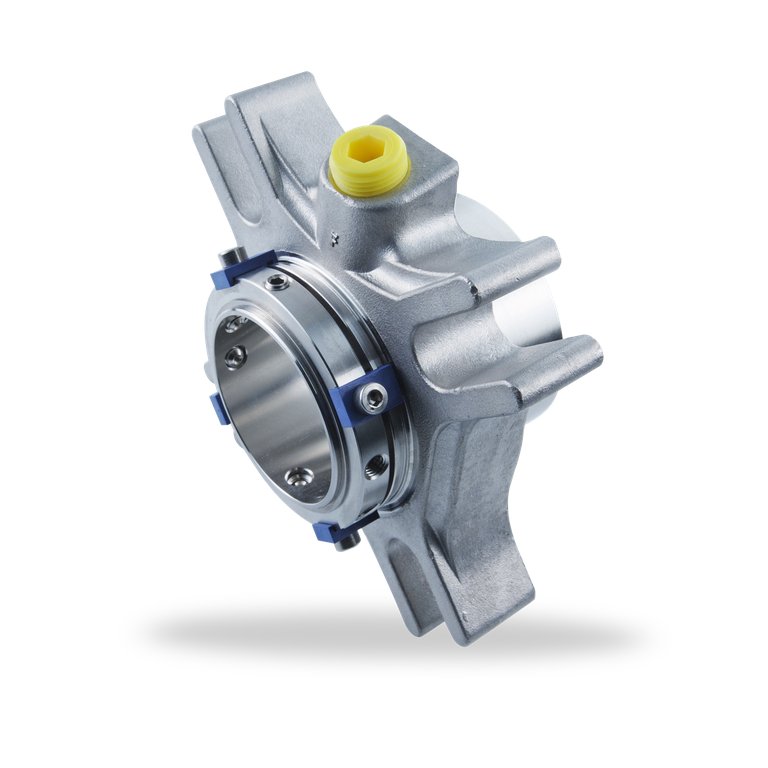

| Item | Description |

| 1 | Bellows unit |

| 2 | O-Ring |

| 3 | Set screw |

| 4 | Seat |

| 5 | O-Ring |

| 6 | Shaft sleeve |

| 7 | O-Ring |

| 8 | Cover |

| 9 | Seal face |

| 10 | O-Ring |

| 11 | Spring |

| 12 | Seat |

| 13 | O-Ring |

| 14 | Drive collar |

| 15 | O-Ring |

| 16 | Set screw |

| 17 | Retaining ring |

| 18 | Assembly fixture |

| 19 | Hex socket head screw |

| 20, 22 | Gasket |

| 23 | Screw plug |

Mtex Dual seals

Features

- Double seal

- Mtex-DN: API Plan 52 (53/54)

- Mtex9-DN: API Plan 53/54

- Cartridge

- Balanced

- Independent of direction of rotation

- Metal bellows

- Stationary Springs

- Pumping device independent of direction of rotation

Advantages

- Ideal seal for standardizations

- Universal applicable for packings conversions, retrofits or OEM

- No dimensional modification of the seal chamber (centrifugal pumps) necessary, small radial installation height

- Trouble-free running due to bellows unit with vibration dampers (essential in case of dry-running)

- No damage of the shaft by dynamically loaded O-Ring

- Self cleaning effect of the bellows

- Straightforward and easy installation due to pre-assembled unit

Materials

Seal face:

Carbon graphite (A), Silicon carbide (Q1)

Seat:

Silicon carbide (Q1), Tungsten carbide (U2)

Secondary seals:

FPM (V), EPDM (E), FFKM (K)

Bellows: Inconel® 718 (M6)

Springs: Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G), Duplex (G1)

Carbon graphite (A), Silicon carbide (Q1)

Seat:

Silicon carbide (Q1), Tungsten carbide (U2)

Secondary seals:

FPM (V), EPDM (E), FFKM (K)

Bellows: Inconel® 718 (M6)

Springs: Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G), Duplex (G1)

Recommended applications

- Process industry

- Chemical industry

- Hot media

- Cold media

- Highly viscous media

- Pumps

- Special rotating equipment

Recommended piping plans

EagleBurgmann TS 2000 Thermosiphon system

Product link:

EagleBurgmann TS2000

Detailed information

on these API 682 4th edition plans:

API Plan 52

API Plan 53A

API Plan 53B

API Plan 53C

API Plan 54

Product link:

EagleBurgmann TS2000

Detailed information

on these API 682 4th edition plans:

API Plan 52

API Plan 53A

API Plan 53B

API Plan 53C

API Plan 54

Product variants

Mtex9-DN

Dimensions, items and descriptions as for Mtex-DN, but with optimized seal face geometry for pressurized operation according to API Plan 53/54. A barrier fluid system (e.g. EagleBurgmann TS2000) is necessary.

Pressure: p1 = 10 bar (145 PSI)

Sliding velocity: vg = 20 m/s (66 ft/s)

Barrier fluid circulation system:

p3max = 16 bar (232 PSI)

Δp (p3 – p1) ideal = 2 … 3 bar (29 … 44 PSI)

Δp (p3 – p1) max = 16 bar (232 PSI)

API Plan 53/54

Pump startup:

Δp (p3 – p1) max = 16 bar (232 PSI) allowed

Dimensions, items and descriptions as for Mtex-DN, but with optimized seal face geometry for pressurized operation according to API Plan 53/54. A barrier fluid system (e.g. EagleBurgmann TS2000) is necessary.

Pressure: p1 = 10 bar (145 PSI)

Sliding velocity: vg = 20 m/s (66 ft/s)

Barrier fluid circulation system:

p3max = 16 bar (232 PSI)

Δp (p3 – p1) ideal = 2 … 3 bar (29 … 44 PSI)

Δp (p3 – p1) max = 16 bar (232 PSI)

API Plan 53/54

Pump startup:

Δp (p3 – p1) max = 16 bar (232 PSI) allowed

Similar products

Cartex Dual seals

- Dual seal

- Cartridge

- Balanced

- Independent of direction of rotation

- Double pressure balanced

- Integrated pumping device

- Variants available: for eccentric screw pumps (-Vario) and gas-lubricated version (-GSDN)

Cartex Single seals

- Single seal

- Cartridge

- Balanced

- Independent of direction of rotation

- Single seals without connections (-SNO), with flush (-SN) and with quench combined with lip seal (-QN) or throttle ring (-TN)

- Additional variants available for ANSI pumps (e.g. -ABPN) and eccentric screw pumps (-Vario)

Cartex ANSI Single seals

- Single seal

- Available for standard (Cartex-ASPN) and big bore (Cartex-ABPN) seal chambers

- Cartridge

- Balanced

- Independent of direction of rotation

- Single seals with flush (-ASPN, -ABPN) and with quench combined with lip seal (-ASQN, -ABQN) or throttle ring (-ASTN, -ABTN)