HA Type

expansion joints

HA Type

expansion joints

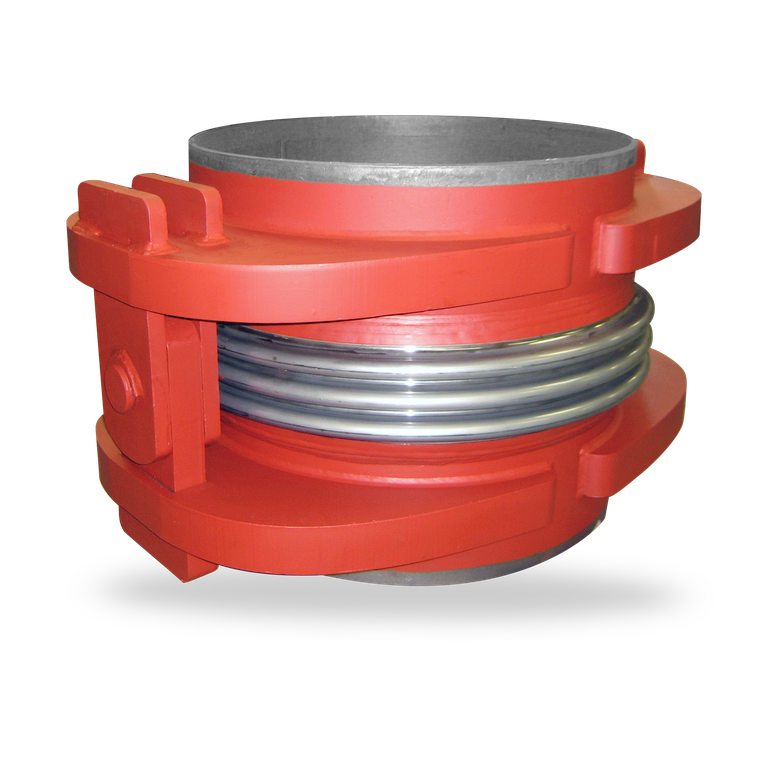

| Item | Description |

| 1 | Carrier ring |

| 2 | Line bellows |

| 3 | Tie rod |

| 4 | Balancing bellows |

| 5 | Flange |

| 6 | Elbow section |

| 7 | Centre spool |

| 8 | Internal liner |

HA Type

expansion joints

Features

- Elbow type pressure balanced expansion joints.

- Pressure thrust eliminated by means of force balancing design principle.

- Designed to apply minimum forces on connecting, load sensitive equipment.

- Mainly for axial and lateral movements.

Advantages

- No need for main anchors to obtain pressure thrust load.

- Minimum load transferred onto connecting equipment – force balancing principle not affected by system pressure fluctuations.

- Highly customizable design: Bellows geometry, Material options and combinations.

- Multiply bellows with low spring rate and high cycle life.

Materials

- Bellows: 1.4541 (AISI 321); 1.4301 (AISI 304); 1.4306 (AISI 304L); 1.4401 (AISI 316); 1.4404 (AISI 316L); 1.4571 (AISI 316Ti); 1.4828 (AISI 309); 1.4547 (254 SMO); 2.4816 (Inconel® 600); 2.4856 (Inconel® 625/LCF); 1.4876 (Incoloy® 800/H)

- Connections: 1.0038 – (S235JRG2); 1.0460 – (P250GH); 1.0315 – ; 1.0254 (P235TR1); 1.0425 – (P265GH); 1.5415 – (16Mo3); 1.7335 – (13CrMo4-5);1.4401 (AISI 316); 1.4404 (AISI 316L);1.4541(AISI 321)

- Flanges: 1.0038 - S235JRG2; 1.0425 - P265GH; 1.0315 - P235G2TH; 1.0254 (P235TR1); 1.0425 - P265GH; 1.5415 - 16Mo3; 1.7335 – 13CrMo4-5;1.4404 (AISI 316L); 1.4436 (AISI 316)

Other materials are available on request.

Standards and approvals

Design codes:

EJMA 9, PED 97/23/EC acc. to EN 13480, EN 13445, EN 14917, AD2000 and ASME B31.3

NDT and documentation:

According to PED 97/23 EC rules and regulations (declaration of conformity)

Documentation can be provided per customer request e.g.:

- Test, measurement or calculation reports

- Material, test or inspection certificates

- Design, type or 3rd party approval

EJMA 9, PED 97/23/EC acc. to EN 13480, EN 13445, EN 14917, AD2000 and ASME B31.3

NDT and documentation:

According to PED 97/23 EC rules and regulations (declaration of conformity)

Documentation can be provided per customer request e.g.:

- Test, measurement or calculation reports

- Material, test or inspection certificates

- Design, type or 3rd party approval

Recommended applications

- Oil and gas industry

- Refining technology

- Power plant technology

- Pulp and paper industry

- Water and waste water technology

- Metal production and processing

- Shipbuilding

- Steam turbines

- Water cooling systems

- Steam transport lines

- Compressor / pumping stations

- Lubrication systems

- Storage tanks

Notes

Tied metal expansion joints might require alignment guides to ensure the expansion joint only see the intended movements.

Product variants

HA1: Elbow type pressure balanced expansion joints

Equipped with min. 2 bellows, internally pressurized.

Mainly intended for axial movement.

Shown with weld ends.

Equipped with min. 2 bellows, internally pressurized.

Mainly intended for axial movement.

Shown with weld ends.

HA2: Universal, elbow type pressure balanced expansion joints

Equipped with min. 3 bellows, internally pressurized.

Intended for axial and lateral movement.

Shown with weld ends.

Equipped with min. 3 bellows, internally pressurized.

Intended for axial and lateral movement.

Shown with weld ends.

Similar products

AN Type expansion joints

- Tied custom metal expansion joints for general pressure applications.

- Designed for, and cover the mid temperature and pressure range for general process equipment.

- Mainly for angular movements.

- Tied metal expansion joints retain pressure thrust developed by internal pressure, through the use of hardware.

AX Type expansion joints

- Untied custom metal expansion joints for general pressure applications.

- Designed to cover the mid temperature and pressure range for general process equipment.

- Mainly intended for axial movements.

- Multiply bellows with low spring rate and high cycle life.

CB Clamshell metal expansion joints

- Bellows or expansion joints split into longitudinal segments for installation without opening pipework.

- Temporary repair solution for damaged expansion joints.

- Can handle axial, lateral and angular movements.

- The permissible combination and magnitude of movements depends on the application and the existing expansion joint that is to be repaired.